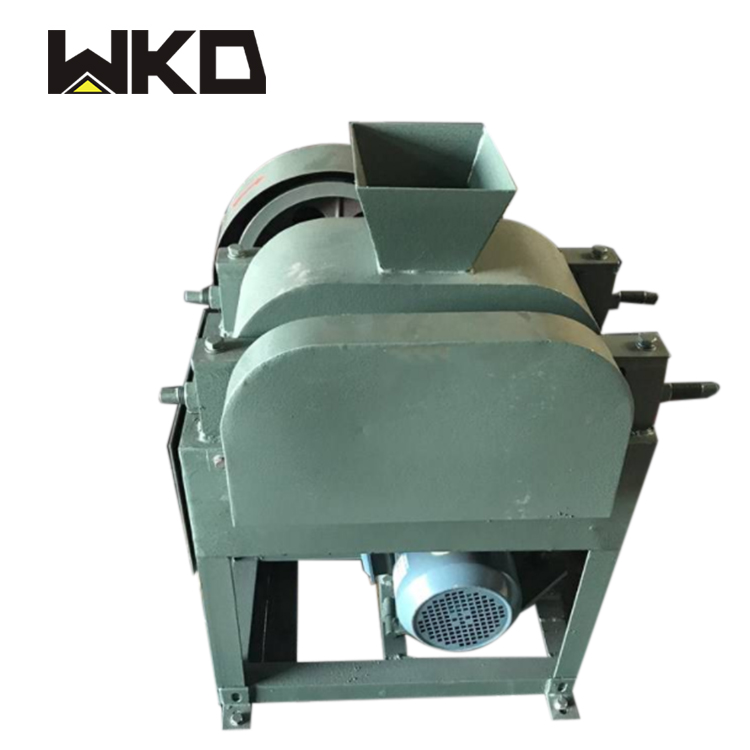

Laboratory Double Roller Crusher

The laboratory double-roll crusher is also called the laboratory roller crusher. Under the action of the relative rotation of the two rollers, the material enters the middle of the counter roller tangentially. As the counter roller rotates, the gap is continuously reduced, and the material is subjected to the grinding roller. The rotating and biting force of the squeeze, crushed under squeezing and biting, broken into fine particles and discharged. The roll gap of the grinding roller can be adjusted arbitrarily between 0mm and 20mm according to the requirements of the crushing particle size to obtain the corresponding particle size. Basic structure: It is mainly composed of fixed rolls, movable rolls, transmission shafts, machine bodies, underframes, covers, long gear covers and other parts.

This machine is the latest generation machine in the world, which is composed of frame, body, rollers, gears and other components. The motor drives the main shaft through the triangle belt, and the gears make the rollers run according to the adjusted trajectory to crush the machine materials in the crushing chamber.

Application

This series of machines is particularly suitable for continuous intermittent crushing of various ores and chemical raw materials, coal, etc. The current model has been comprehensively improved, which has greatly improved production efficiency, and is more suitable for modern laboratory support.

It is used in coal, electric power, chemical industry, building materials, scientific research and other industries. The roller crusher belongs to the medium crushing and fine crushing of raw materials. The crushing mode is double roll extrusion.

The crushed material should be brittle. The shape of the crushed material is mostly regular flake. The compressive strength of the crushed material is not more than 60MPa, and the hardness is grade 3. When the moisture content of the material is more than 6%, the particles will stick.

Features

1. Simple structure, flexible adjustment of discharge granularity;

2. Equipped with dust-proof device to prevent dust from spreading out and polluting the environment;

3. Using high-quality materials, strong and durable;

Production Specifications

Details Images

Company Profile

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters

and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installationteam.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England,Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

To View More

FAQ

Q1:Are you a manufacturer of mining equipment?

A1:YES, with more than 15 years production & sales experience

Q2:Could your company help design mineral flow chart?

A2:YES, we have about 20 people team of technician and can design a whole set of processing line.

Q3:Can you provide sample testing?

A3:YES, we have mineral testing laboratory and can do sample testing.

Q4:For efficient communication, what information should you provide before quotation?

1) what's your processed material? if it's rock ore, do you have mineral report?

2) what's your capacity(tons per hours)?