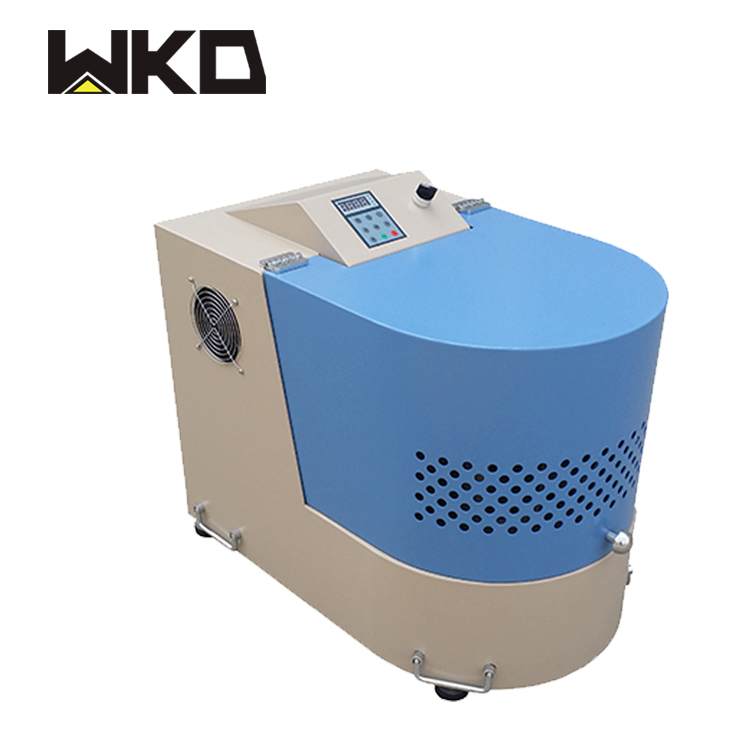

Laboratory Planetary Ball Mill

Vertical planetary ball mill is a necessary device of high-tech materials mixing, fine grinding, sample making, new product development and small batch production. Planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for R&D institution, university, enterprises laboratory to get samples (each experiment can get four samples at the same time). It gets powder samples under the vacuum state when equipped with vacuum ball mill tank.

Application

Vertical planetary ball mill is a necessary device of high-tech materials mixing, fine grinding, sample making, new product development and small batch production. Planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for R&D institution, university, enterprises laboratory to get samples (each experiment can get four samples at the same time). It gets powder samples under the vacuum state when equipped with vacuum ball mill tank.

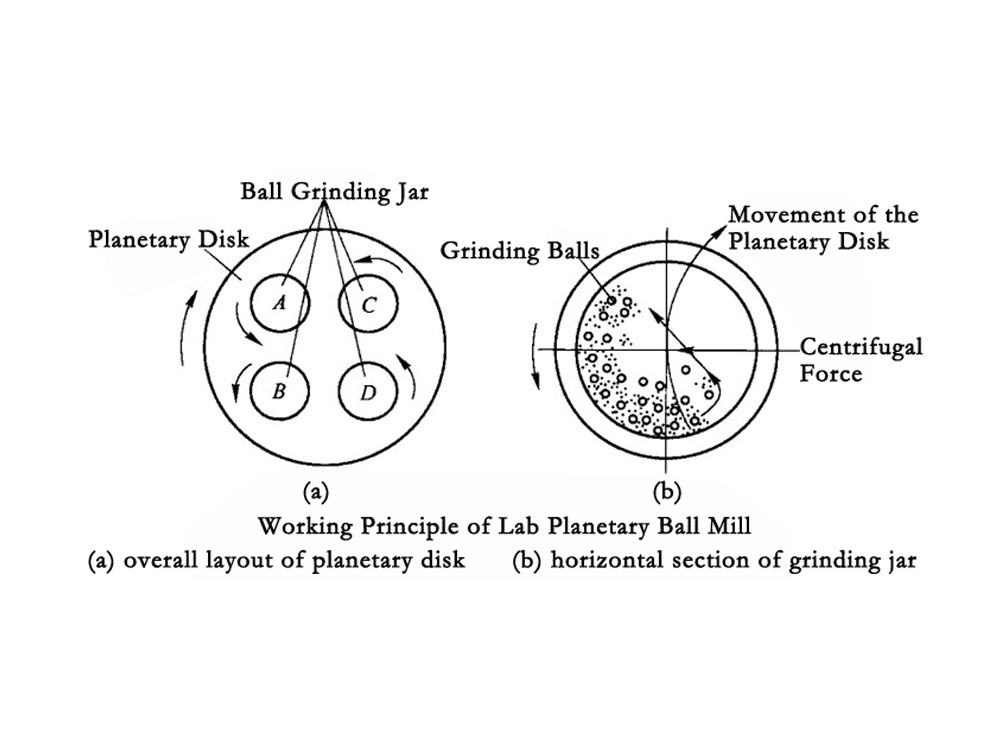

Working Principle

Planetary Ball Mill has four ball grinding tanks installed on one turntable. When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder. Various kinds of different materials can be ground by the mill with dry or wet method. Minimum granularity of ground powder can be as small as 0.1μm.

Features

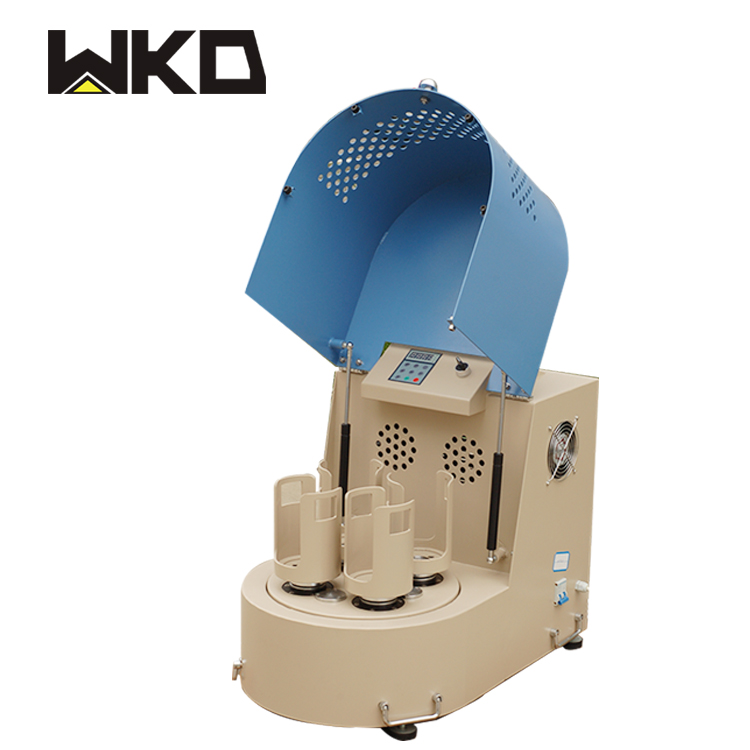

Vertical planetary ball mill shell is welded with thick steel plate, which has high strength, impact resistance, deformation resistance, fine workmanship, strong and beautiful appearance. The material of mechanic parts is strictly processed by heat treatment process and numerical control processing technology. The gear box is adopted with quasi-sealed groove embedded structure, and the drive gear is made of wear-resistant precision gear. The machine frame and structure are fully considered in design to ensure the stable, safe and reliable operation of the ball mill under long-term and high load conditions, and to effectively achieve the effect of noise reduction in the operation of the machine. The liquid oil self-lubricating device is designed with low noise and high intensity, and it is equipped with a liquid oil level meter for easy replacement. The supporting lifting and feeding devices are adopted with integrated design. The feeding device incorporates the technology of vibrating screening and discharging for simple and convenient operation. It realizes easy and fast picking up, discharging and loading of mill jars, reduces labor intensity and improves production efficiency. With the touch screen of micro-computer, machine operation is becoming convenient, the interface is more simple and intuitive,forward and reversal alternating control can be achieved easily. It owns functions of timing and power-off memory.

1.Stable revolving speed of the gear transmission ensures the consistency and repeatability of the experiment.

2. Planetary movement principle is adopted in the machine, which has high speed, large energy, high efficiency, small Granularity.

3. Four powder samples from different sizes and different materials can be produced at one time.

4. The machine is controlled by frequency converter, you may choose ideal rotating speed according to expected experimental result. The converter is equipped with device of under voltage and over-current to protect the motor.

5. The planetary ball mill has functions of timing power off, self-timing forward and reversal rotating. You may choose freely any operation modes of one-way direction, alternation, succession, time setting according to experimental needs, so as to improve efficiency of grinding.

6. Technical features of Ball Mill: Low center of gravity, stable performance, compact structure, easy operation, reliable safety, lower noise, small loss.

7. Safety switch is installed on the machine to prevent safety accident if the safety cover is opened while machine is running.

References for Matched Mill Jars and Balls

As a professional manufacturer and supplier of planetary ball mills, we provide all kinds of mill jars in full sizes covering 304 or 316 stainless steel mill jars, tungsten carbide mill jars, agate mill jars, corundum mill jars, zirconia mill jars, nylon mill jars, PU mill jars, PTFE mill jars and etc.

Details Image

Production Specifications

Company Profile

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters

and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installationteam.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England,Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

To View More

FAQ

Q1:Are you a manufacturer of mining equipment?

A1:YES, with more than 15 years production & sales experience

Q2:Could your company help design mineral flow chart?

A2:YES, we have about 20 people team of technician and can design a whole set of processing line.

Q3:Can you provide sample testing?

A3:YES, we have mineral testing laboratory and can do sample testing.

Q4:For efficient communication, what information should you provide before quotation?

1) what's your processed material? if it's rock ore, do you have mineral report?

2) what's your capacity(tons per hours)?