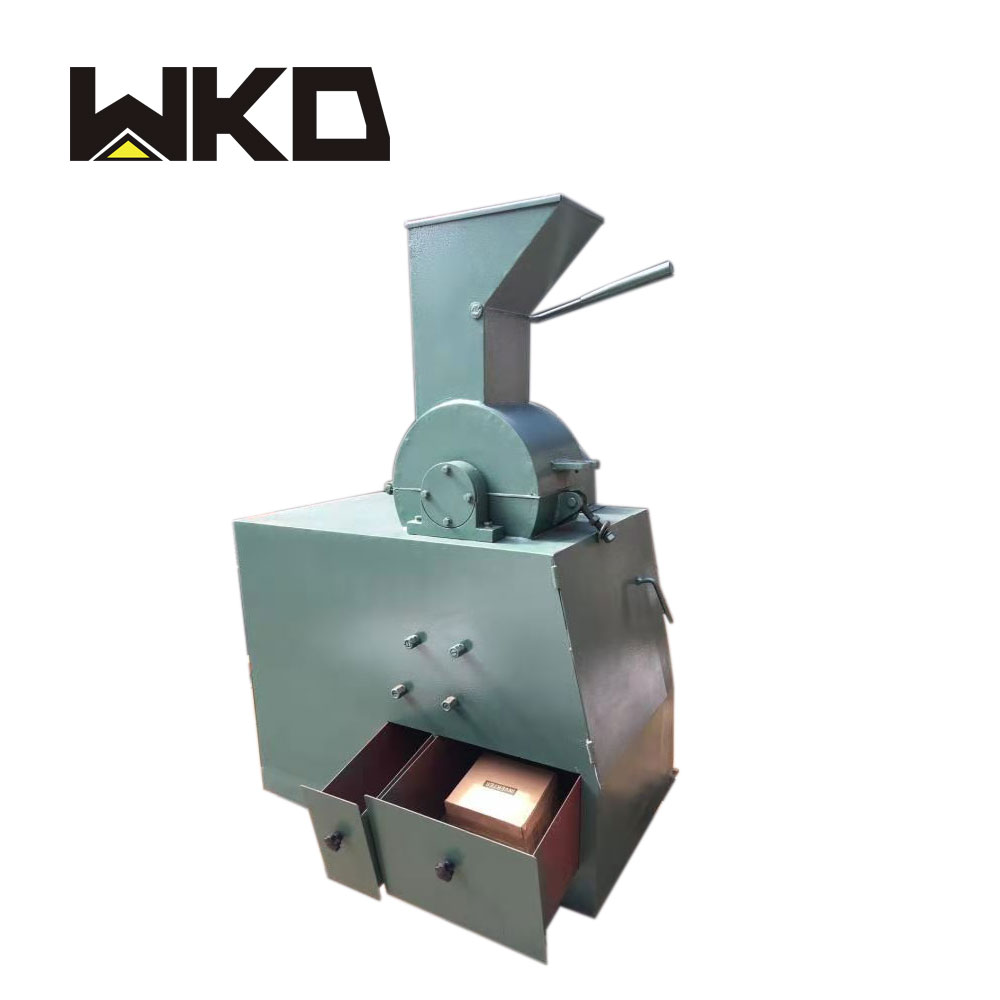

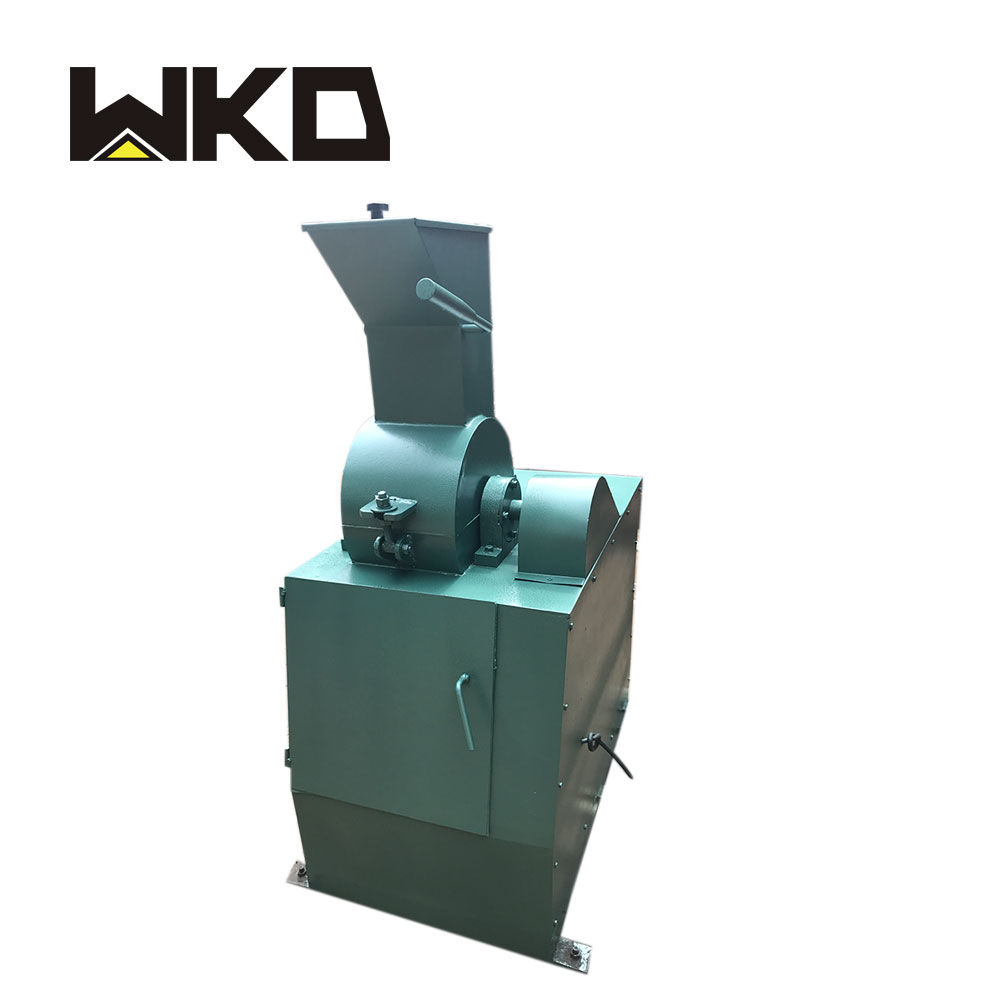

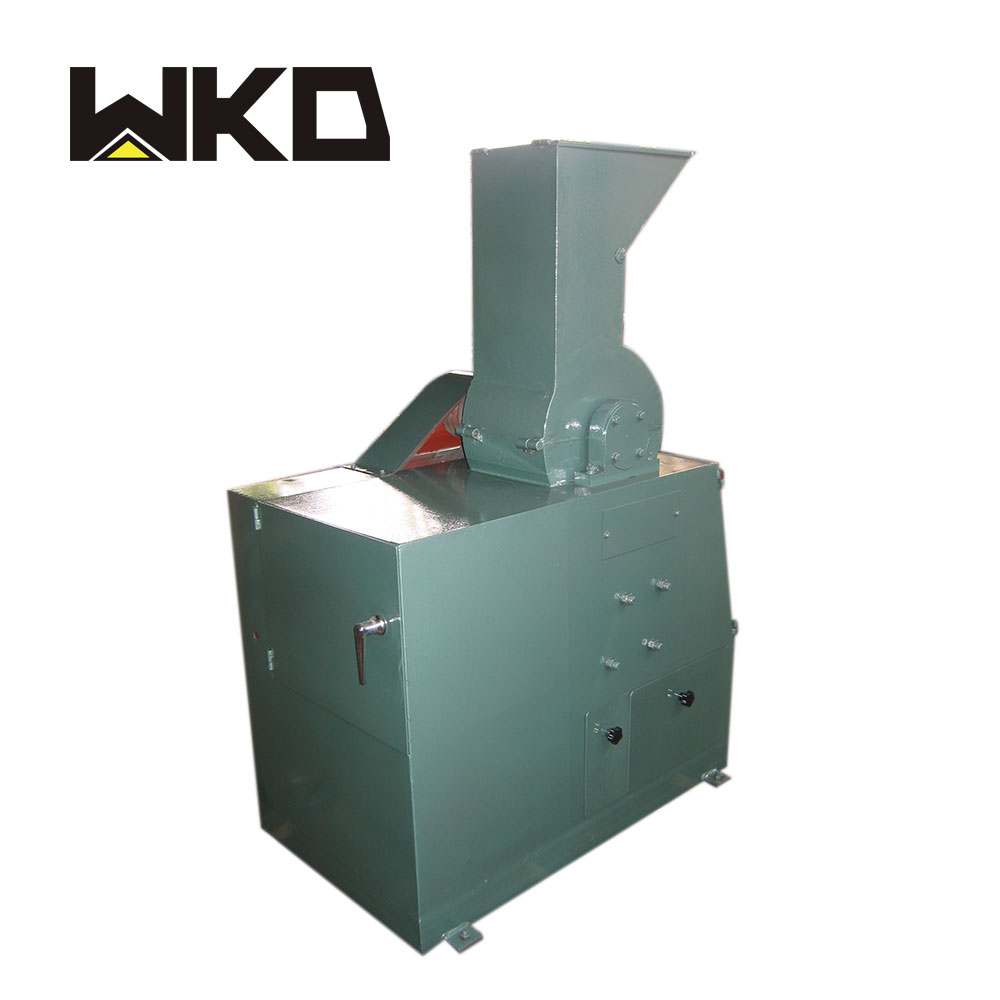

Laboratory Hammer Crusher

The small hammer mill adopts high speed rotation hammers crushing, characterized with simple structure, large crushing ratio, and high-efficiency features, running with wet and dry crushing work. The hammer mill is the best to crush medium hardness and brittleness materials especially apply to the mining area, cement, coal, metallurgy, building materials, roads, fuel chemical departments. This hammer machine can adjust the grate gap to change the output size according to user requirements.

Hammermill grinder applicate on various medium hardness and weak abrasive materials. The materials anti compressive strength less than 100Mpa, water less than 15%. Like crushing the coal, salt, white sub, gypsum, brick, limestone, etc. Hammer mill crusher also used for crushing fibrous structure, strong elasticity and toughness of wood, paper or crush the asbestos-cement waste to recover asbestos fiber, etc.

Features

1.Can crush medium hardness and brittleness materials.

2.Can run with wet and dry crushing work.

3.Can adjust the grate gap to change the output size.

4.Large crushing ratio, homogeneous discharge material and high efficiency features. 5.Hammer is adopting full width of the high

manganese, and crushing material completely;

the main parts use special material, the using life 3-5 times than normal materials.

6.Crushing chamber is precision casting by ZG45, wear-resistant and durable;

can effectively prevent contamination and overheating.

7.Complete sealed design,no dust pollution, comply with environmental requirements.

8.Working on the level ground ,low noise, don't need any basic fixed.

9.With opened door,easy operation and convenient maintenance,low cost of production.

Working Principle

The crusher hammer mainly crushes the materials by impact crashing, the crushing processing is like this, the materials put into the crusher, broken by high-speed rotation cashing, and with high speed cashing in baffles and screen bars, the broken material been repeatedly conflict, the bigger particle materials hammer again on the screen bars by grinding, squeezing and crushing, materials extruded from the gap of hammers.

Electric hammer mill main parts are rotors with hammers, the rotor includes shaft, pins and small hammers. Hammer grinder with Intelligent PLC control, touch screen operation, auto finishes the crushing work. Automatic clean sample device, never blocking if the moisture of the material less than 25%. With safety fault alarm and inquiry system. The main parts use special material, using life 3-5 times than normal materials. With an automatic dust removal device make sure no dust leakage, comply with environmental requirements. Complete sealed design, comply with safety working requirements. With opened door easy to daily maintenance. Working on the level ground, don’t need any basic fixed.

Details Images

Production Specifications

Company Profile

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters

and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installationteam.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England,Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

To View More

FAQ

Q1:Are you a manufacturer of mining equipment?

A1:YES, with more than 15 years production & sales experience

Q2:Could your company help design mineral flow chart?

A2:YES, we have about 20 people team of technician and can design a whole set of processing line.

Q3:Can you provide sample testing?

A3:YES, we have mineral testing laboratory and can do sample testing.

Q4:For efficient communication, what information should you provide before quotation?

1) what's your processed material? if it's rock ore, do you have mineral report?

2) what's your capacity(tons per hours)?